Questions & Answers

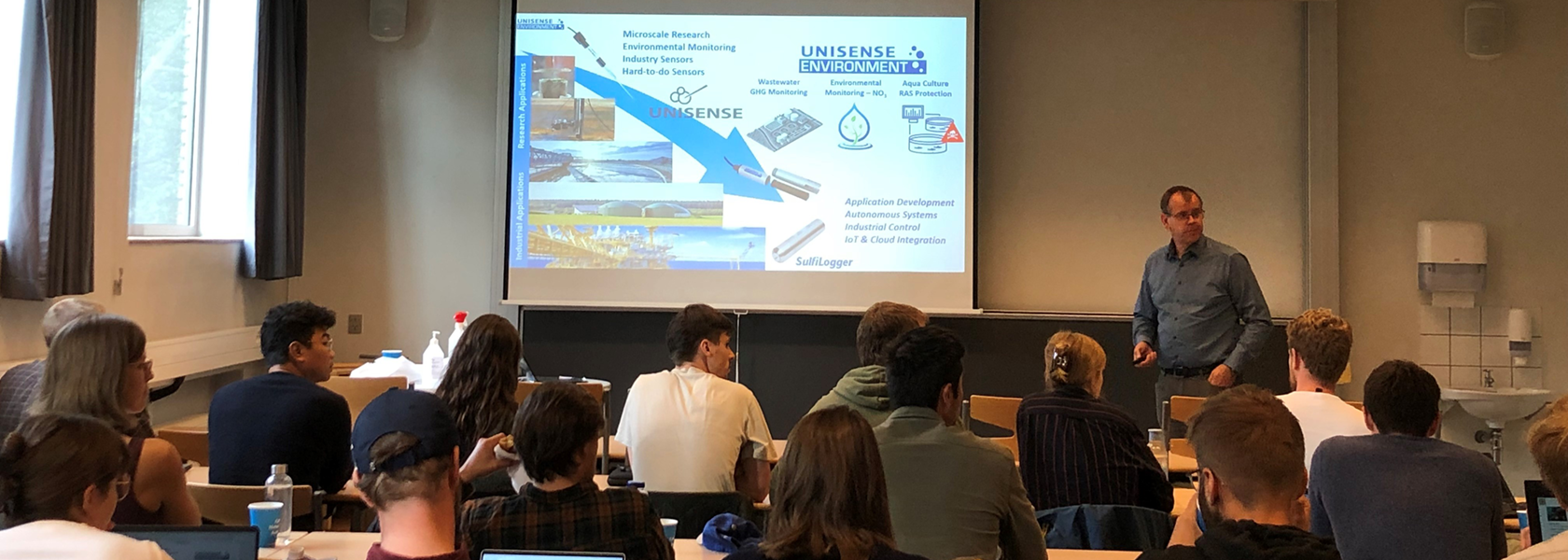

Deammonification optimization (Unisense Environment)

The online NH4 ISE sensors are routinely process calibrated and reliably used for ammonium base aeration controllers throughout the wastewater treatment plant. The N2O-signal fed into the aeration timing loop of the deammonification controller.

The controller is explained in GHG simulations and controller optimizations of the deammonification process, WEFTEC 2018, Water Environment Federation (2018), pp. 4000-4017.

Emission calculation based on liquid-phase measurement

Nitrous oxide emissions are calculated from liquid phase measurements in real time using a modified Henry’s law that describes the transfer of gases from liquids. The input parameters are the tank total airflow, tank dimensions (depth above diffusor and surface area of aerated field) as well as the temperature and N2O concentration. The complete formula has been collected here including references for full-scale scientific validation.

An excel sheet for validation of calculations is available from Unisense Environment on customer request.

Side-by side measurements with off-gas hoods have also been extensively done and show good agreement when sampling is done next to each other, see an example in this technote. In an ongoing publicly funded project (N2O Mobile), further extensive comparison of the methods for full plant applicability is being done. A validation of liquid to gas emissions has been done for a full wastewater plant with remote sensing in this finalized, publicly funded project: AWAIRE: Development and testing of techniques for measuring N2O emissions from wastewater treatment plants.

Calibration temperature sensitivity

A calibration of the N2O sensor is done at process water temperature. It then has a window of +/- 3 °C in which it measures with high accuracy. If the process temperature is outside of the calibration window, the uncertainty of measurement becomes larger than 2.5% and are mainly driven by N2O solubility changes in wastewater as a function of temperature. For these cases the N2O wastewater system gives a notification to SCADA/PLC on digital communications and on the controller itself.

Typically, the recommended calibration every 2 months can follow the changes in water temperature. A practical way of enlarging the temperature window without the need for recalibrating often is to calibrate at a temperature slightly above or below process temperature when fast changes are expected (lower in autumn, higher in spring).

High DO – Skyway plant

The N2O sensor has a chemical oxygen reductant built into the measuring tip. Standard sensors can tolerate and are operating normally at DO concentrations up to 4-6 mg/l. Exposure time is also a relevant factor. For applications with higher DO, customized sensors can be supplied, as was the case for the Skyway plant.

Is the correlation based on the DO/MLSS/pH vs N2O or the emission factors? (Halton Region/Aquafy)

The correlation is based on the sensor measuring N2O in mg/L.

What kind of correlation analyses did you apply? (Halton Region/Aquafy)

Spearman’s rank correlation was used.

We are happy to answer any additional questions

If we are online and available to chat, you can also click the blue icon to the right.