Sensor Placement in the Wastewater Treatment Process

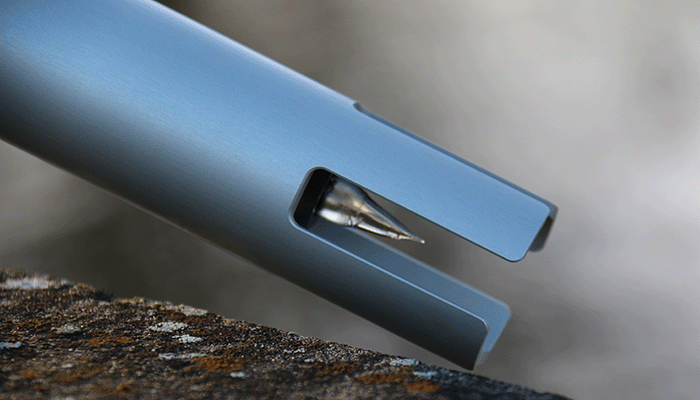

This page will give you a quick overview of what you need to consider when placing nitrous oxide sensors in your wastewater treatment process.

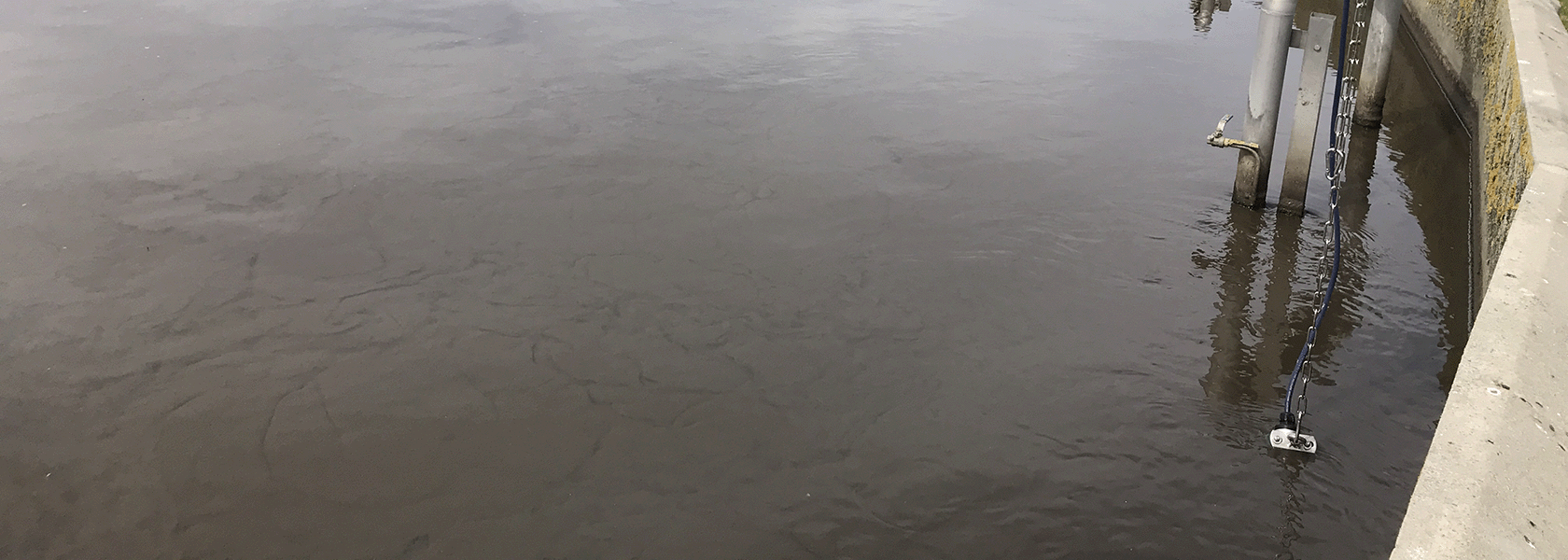

You must mount the sensors in such a way that they cannot be physically damaged by hitting any walls or other objects. We recommend that you consider a suitable mounting solution, such as the chain mount, to ensure that the sensor cable does not carry the weight of the sensor.

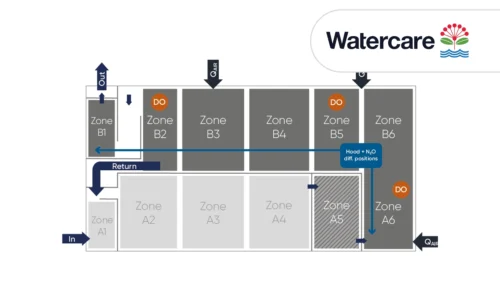

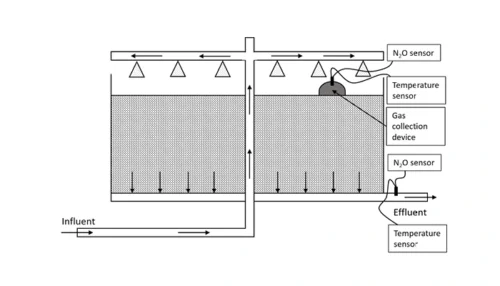

The ideal location of sensors in biological wastewater process depends on the type of reactor, flow, aeration pattern, and the processes applied in your treatment plant. When both nitrification and denitrification are used, you should monitor both processes. When you calculate emissions, the representative positions are most important. If you want to test mitigation measures, it would be beneficial for you to measure a parallel lane as control.

The guidance on this page is based on overall assumptions. Contact us to discuss your specific application.

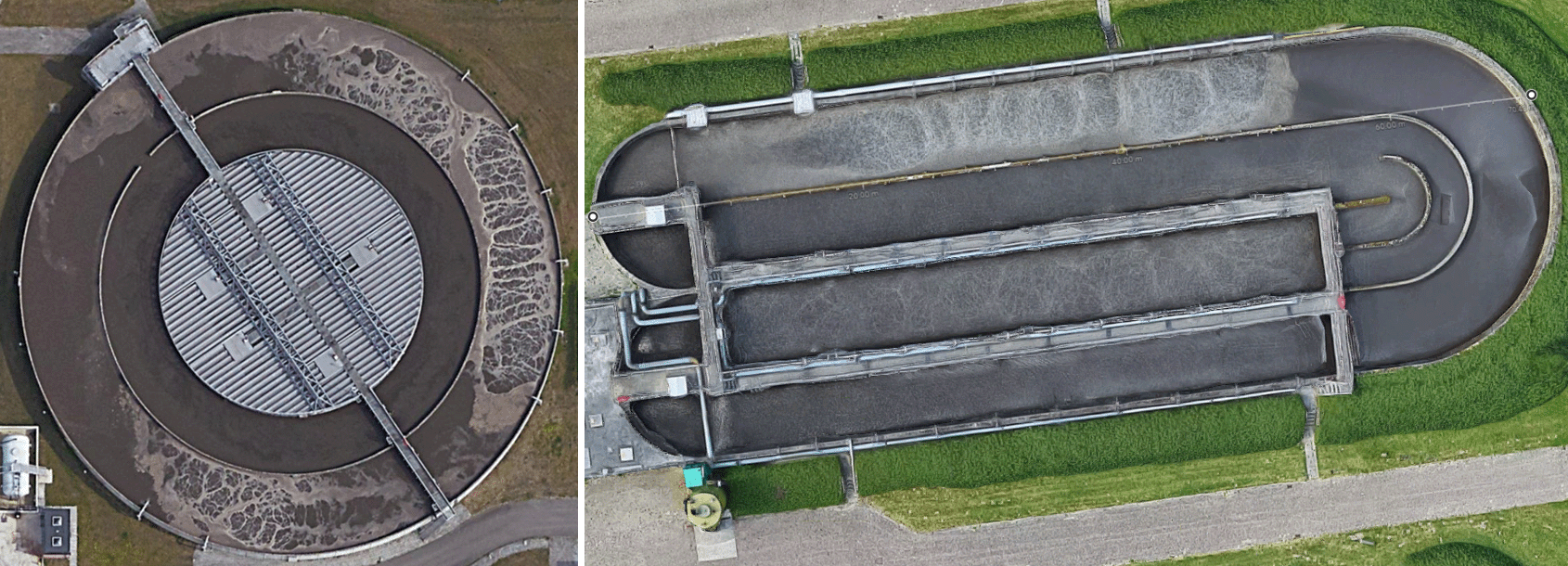

Raceway or Carrousel Reactor

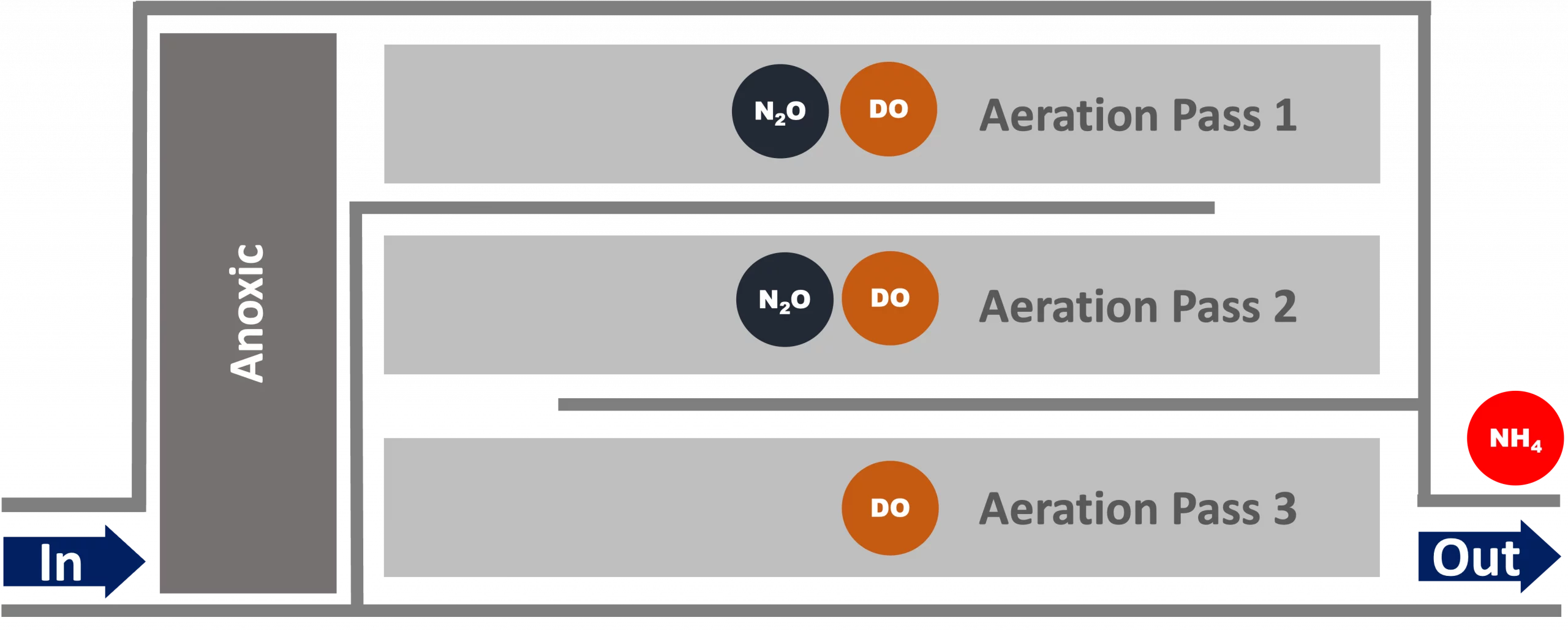

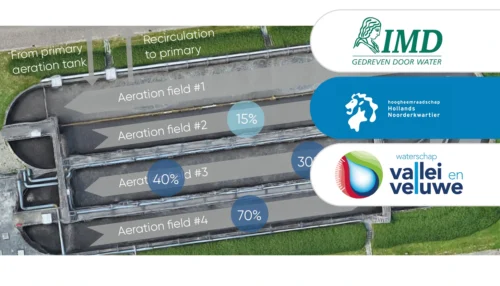

Raceway and carrousel reactors are characterized by partial recirculation of water. These reactors can either be with separate zones performing nitrification/denitrification, or they can be operated with intermittent aeration, separating the processes in time.

If you are using intermittent aeration, a single sensor is often sufficient to monitor a single lane. If your plant features surface aerators, you should place the sensor just before the rotor.

You should place sensors in locations of laminar flow, away from bends in the tank.

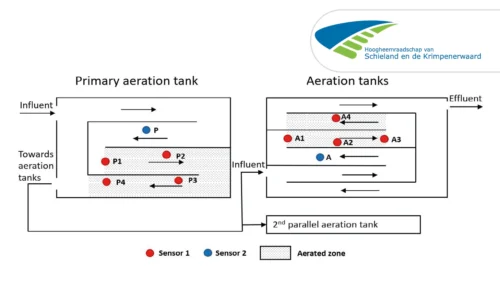

If your plant has separated zones, you should place one sensor at the end of the denitrification zone and another at about 1/3 of the aerated zone. Learn more in our tech note: Positioning of N2O Sensors in Typical Biological Wastewater Treatment Processes.

Plug-Flow Reactors

In a nitrifying plug flow reactor, inherent concentration gradients lead to a more ambiguous situation that requires some testing of positions. You should use two sensors to monitor one lane.

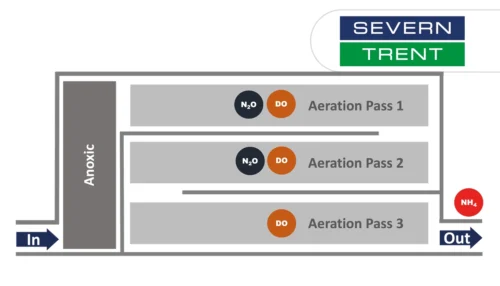

In a nitrification-only situation, you should place one sensor at 1/3 of the aerated zone while you apply another sensor to scout for elevated concentrations along the lane. Learn how Severn Trent did at the Spernal sewage treatment plant, their resource recovery and innovation centre.

When you move one sensor into position, it is important that you leave the other sensor in place to have a reference that enables you to identify the effect of variations of the process over time.

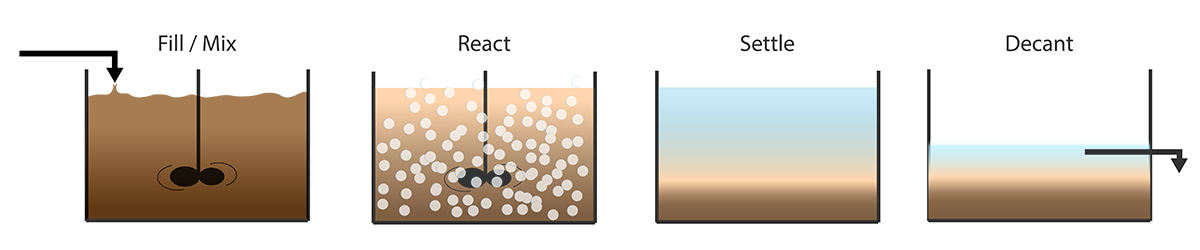

Sequential Batch Reactor (SBR)

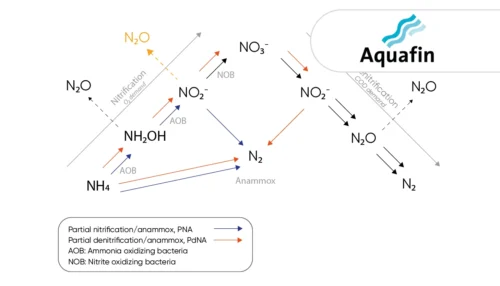

In an SBR, you only need a single sensor to monitor the whole reactor, as it is considered to be completely mixed. Irrespectively of the type of biological process being used; carbonaceous treatment, nitrification, denitrification, or deammonification. Note that deammonification is considered a high risk process for N2O emissions.

Learn how the main Belgian utility for sewer transport and wastewater treatment, Aquafin, reduced emissions in this tech note: N2O Sensor Controls Emissions from Deammonification Processes.

Tech Notes & References

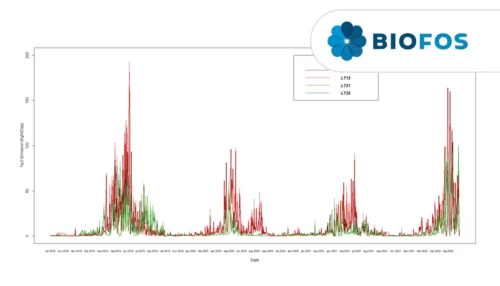

Two liquid phase N2O sensors accurately represent process dynamics and emissions in most common raceway and recirculation reactors.

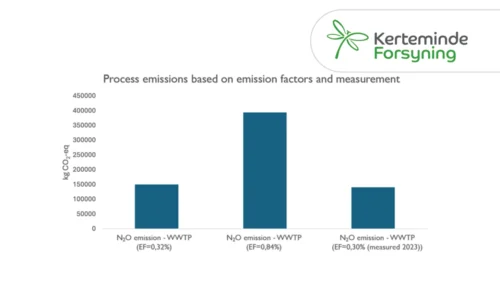

Learn how Kerteminde Forsyning applied nitrous oxide data to reduce the formation of N2O while maintaining low nitrogen emissions

Case Study: Full-scale comparison of N2O emissions determined by liquid sensors and off-gas measurement

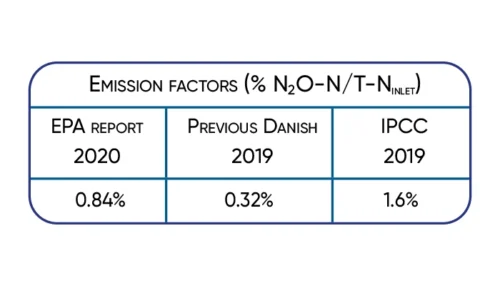

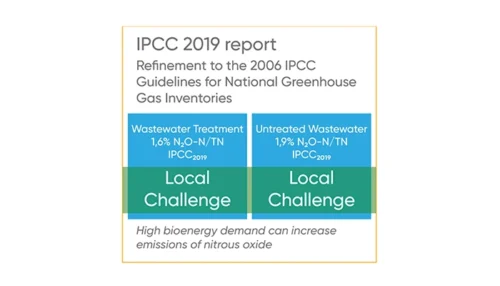

Significant 3-fold increase in IPCC2019 wastewater N2O emission factor supported by Danish studies.

A case study from Kralingseveer WWTP in the Netherlands explores the influence of sensor placement.

Based on data from Danish WWTPs through advanced online-control.

Learn about the results from N2O monitoring in the activated sludge tanks at Severn Trent’s Spernal sewage treatment plant

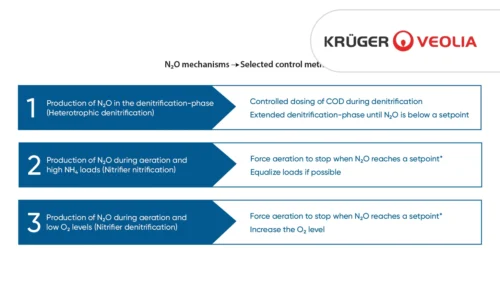

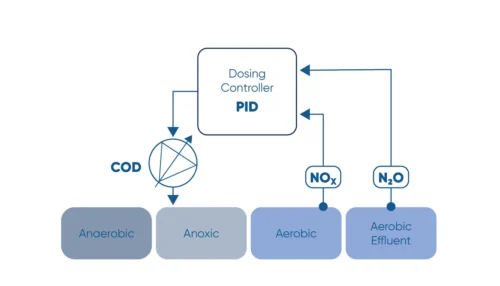

Monitor the N2O concentration in the liquid and use N2O as a control parameter for carbon dosage in the denitrification process.

Learn how the water utility Aquafin controls emissions from deammonification processes using the the N2O Wastewater Sensor

Greenhouse gas emissions at wastewater treatment plants are coming into focus as the water industry works to reduce its climate footprint

The investment costs had initially deterred us somewhat. However ...

A study of three very different WWTPs in Denmark: Bjergmarken (125,000 PE), Holbæk (60,000 PE), and Hvalsø (11,570 PE)

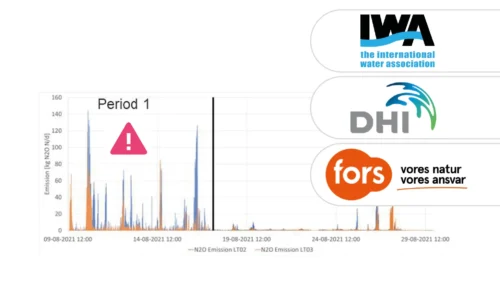

The available data show that the nitrous oxide emission varies in time and between wastewater treatment plants.

Information regarding N2O emissions from trickling filters is limited, partly caused by the difficulties in capturing off-gases.

Significant 3-fold increase in IPCC2019 wastewater N2O emission factor supported by Danish studies.